We are going to delve into the details about ordering and manufacturing signs from Sign Fab! From quoting to delivery, we will take you step-by-step into the process of manufacturing a sign with us.

The first step to any sign is getting a quote. We’ve covered this topic before, so we’ll keep it short and get straight to basics. When you request a quote, it makes things go a lot faster if you make sure you have as much of the following as possible:

Preparing the Quote Request

To help our sales staff there are a few things we need to process your quote faster.

Contact Information for your company. This is especially important if you are a new customer.

- Business Name

- Contact name, phone number, shipping and billing address and email

Artwork for the sign. Make sure everything is drawn to scale in the artwork.

– Preferred formats include: PDF, AI, EPS, CDR

Measurements of the sign.

- If possible, include the signs dimensions in your artwork.

Face Options. Know ahead of time if your sign will need something specific or special, such as vinyl or digital print. You can find color charts in our catalog here.

Painted Returns. This too, will increase the quote, so it’s best to make sure we know so your quote accurately reflects the sign.

Mounting. You’ll need to know how the sign is going to be mounted, and whether it’s remote, self-contained, or raceway mounted.

FINALLY, Sending the Quote Request

After you’ve gathered all of this information, feel free to send us a well-documented quote request! Send your quote request to your sales representative or [email protected]. Following the above-mentioned guidelines will also help with processing your quote faster.

Ordering Process

When you’re ready to place an order, we’ll need a few more details to ensure fast production. The most important information needed that often gets overlooked at this stage is color options. We have a wide selection of color choices available. To see our color selection, click here to view our 2024 Sign Guide catalog. Here are a few things that you’ll need to choose colors for:

• Acrylic face color

• LED color

• Trim color

• Return color

• Raceway color

• Vinyl colors

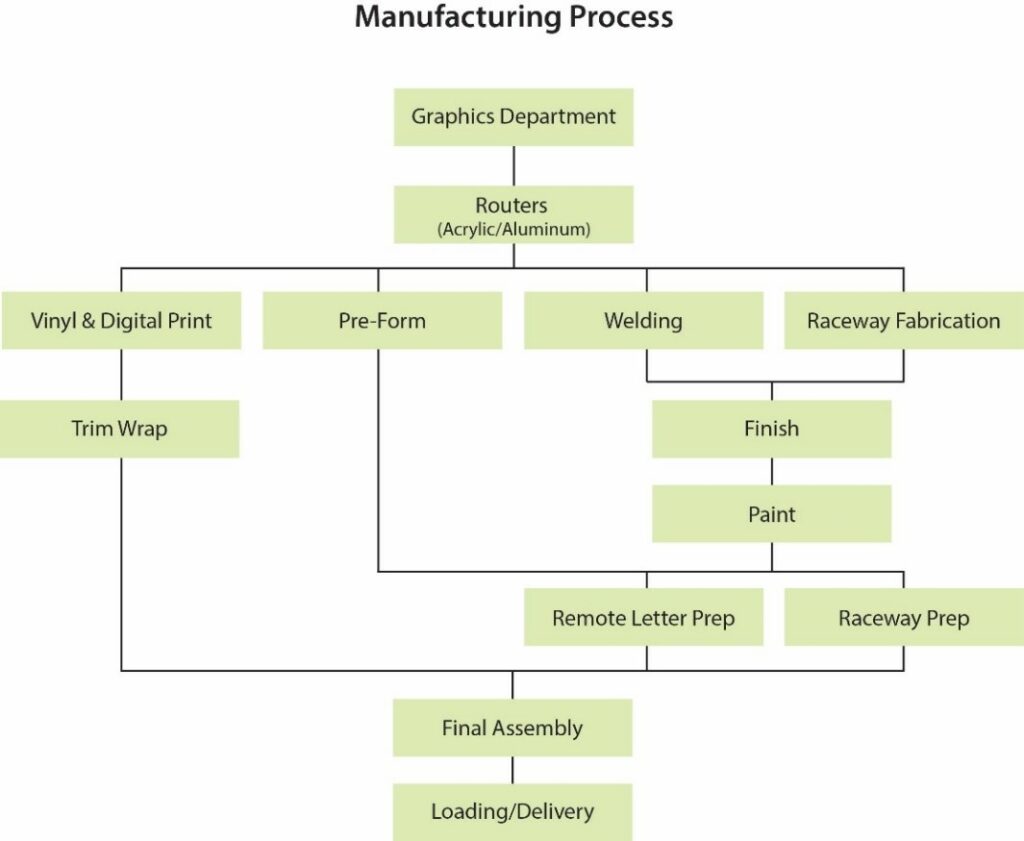

After placing down payment on your order is the Graphics Department.

For a quick reference click here for our order process.

Graphics Department

– Cleans artwork

– Makes sure stroke widths are optimal for -lighting purposes

– After Cleanup our team produces drawings with correct colors and accurate dimensions

– After artwork approval, LED layout and if necessary, mounting patterns, the sign moves on to the routers

Routers

- Aluminum cans and acrylic faces are machine-routed

- Once finished it goes to the finishing room

Vinyl and Digital Print –

- If required, vinyl or digital print is placed on the sign faces

Once finished it goes to the trim room

Trim Wrap

– This step is where the sign face gets trim.

– After the trim is in place and has set it heads to final assembly.

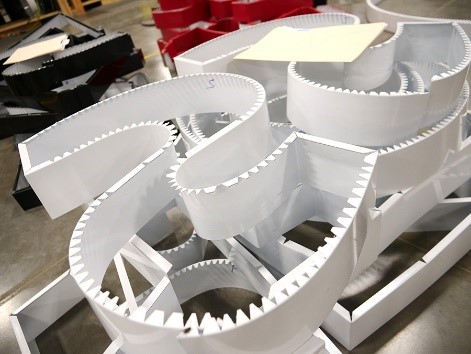

Pre-form

– Most common route for our signs

– After aluminum backs are routed, they head to pre-form where the returns are machine-bent from pre-finished aluminum

– Aluminum then stapled to the backs

– The finished can then goes to caulk and peel station

– Once finished they head off to final assembly

Welding

– Some signs, such as a complex logo or capsule or reverse channel letter signs, require welding instead of pre-form

– Welders carefully measure out and weld together backs or fronts of signs to the aluminum return

– After this step is finished, they go off to our finishing department

Raceway Fabrication

- If a raceway is needed the specifications go to our raceway department for fabrication

- Most raceways are made of pre-fabricated materials, but some do require special routed parts to finish construction

- After the fabrication is finished, they also go off to our finishing department

Finishing

This is where the cans get washed and sanded. Prepping them for paint.

Paint

– Paint is applied to the cans as necessary

– High-quality paint is used to ensure no fading for the life of the sign

Remote Letter Prep

- Remote letters and signs receive final touches before going to final assembly

- This includes, as previously mentioned, caulk and peel if necessary, and the installation of mounting hardware

Raceway Prep

- During raceway prep, mounting holes are drilled and the raceway is prepared for final assembly

Final Assembly

- Cans are mounted to the raceways

- LEDs are inserted into each letter, logo, and capsule

- Faces are installed and secured

- After ensuring that all signs have been manufactured to our high-quality standards, they head off to the loading and delivery area.

Quality Control

- Every sign that leaves our shop goes through thorough process to ensure it matches our high standards

Loading/Delivery

– Enjoy Sign Fabs exclusive delivery service at no charge in our delivery area

– All signs are carefully packaged

– All signs are shrink wrapped

– All signs are mounted on our delivery trucks

– Necessary accessories are compiled into their specific boxes and loaded on delivery truck

If you have any questions, don’t hesitate to call or e-mail us and ask! Customer service is very important to us, and we want to make sure you know what to expect when it comes to quoting, ordering, manufacturing, and delivery.